Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

PEEK material is a new type of semi-crystalline aromatic thermoplastic engineering plastics, it has excellent physical and mechanical properties, the use of machining or injection molding process PEEK products with light weight, super wear-resistant, self-lubricating, low noise, corrosion resistance, fatigue and other characteristics of the advantages of being widely used.

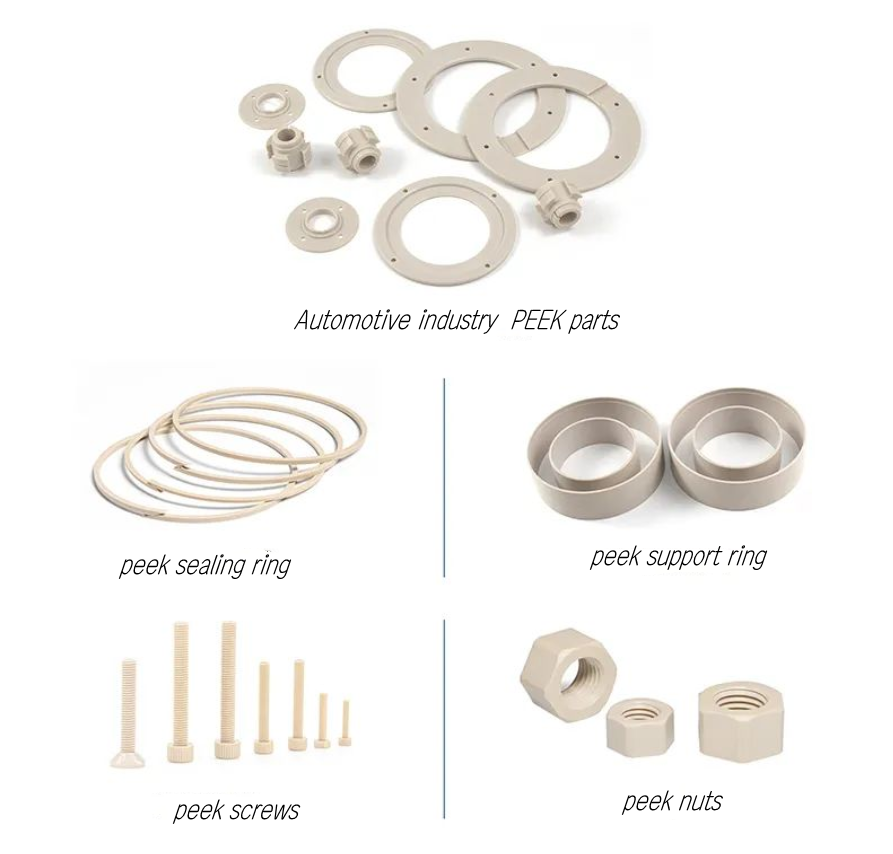

PEEK material can replace metal, stainless steel and titanium, used in the manufacture of engine internals, the manufacture of automotive gaskets, bearings, clutch gears, seals and a variety of other parts, in addition PEEK material can also be used in the transmission, brakes and air conditioning system of the car.PEEK has been successfully used in the automotive manufacturing industry, due to its good friction resistance, can replace metal (including stainless steel, titanium) to manufacture Engine internals, automotive bearings, seals and brake pads, etc.

The use of PEEK good friction resistance and mechanical properties, can replace metal as the manufacture of automotive ABS anti-lock devices, automotive seals, gaskets, bearings and other parts, in the vehicle's transmission system, brake system, steering system, seating system and other applications, can be achieved lightweight. Currently, the automotive industry is increasingly demanding the dual performance of smaller vehicle weight, cost and greater product performance, especially the pursuit of automotive comfort and stability, the corresponding air conditioning, power windows, airbags and ABS braking systems and other devices are increasing in weight . The use of PEEK resin good thermodynamic properties, friction resistance, low density and easy processing of automotive parts, processing costs are greatly reduced at the same time, not only can reduce the weight of up to 90%, and can ensure a long service life so PEEK as a replacement for metal stainless steel and titanium used in the manufacture of engine hood materials, manufacturing automotive bearings, gaskets, seals, clutch gear rings and other various PEEK is used as a replacement for stainless steel and titanium in the manufacture of engine covers, bearings, gaskets, seals, clutch rings and other components, as well as in transmission, brake and air conditioning systems.

PEEK is used in automotive fuel management systems because of its excellent fatigue and chemical resistance properties. Because of its light weight, it is replacing a variety of reactive metal or aluminum components used in transmission, braking and air conditioning systems, including piston units, seals, gaskets or bearings, which can result in significant reductions in vehicle weight and noise.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.