Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Keywords: automotive interior and exterior trim; additive prototyping prototype; 3D printing technology; reaction injection molding

Exterior and interior parts are important components of the structure of the car, the exterior parts of the car parts such as front and rear bumper skins, spoilers and side skirts and other parts; interior parts are the parts that come into contact with the interior of the vehicle, such as the instrument panel, sub-instrument panel and door guards, etc.. It is because the interior and exterior parts are very important to the appearance and use of the car, and these parts to injection molding process is predominant, the reason is that injection molding process parts molding consistency is better, can be formed relatively more complex shape parts, high production efficiency, parts price is relatively cheap, the disadvantage is the formal production mold price is higher. Therefore, in order to ensure that the actual parts can meet the visual effect of the design, ergonomic requirements and meet the requirements of the assembly structure, it is necessary to arrange for the manufacture of Rapid Prototyping (RP) prototypes before the development of formal molds for vehicle installation verification, and the installed parts can also meet the pre-build parts requirements such as the announcement of the model. The use of rapid prototyping prototype inspection design solutions can significantly accelerate the time to market, reduce development costs and shorten the product development cycle.

At present, the domestic and foreign automotive industry mainstream rapid prototyping of interior and exterior parts manufacturing methods are mainly divided into CNC machine tool processing parts, 3D printing, Vacuum Casting mold (Silicone Mold and fiberglass mold) etc., of which 3D printing is the rapid development of the method in recent years.

1\CNC machine processing parts

CNC machine tool processing parts generally refers to the use of CNC machine tool equipment directly according to the design program processing materials for acrylonitrile-butadiene-styrene copolymer (ABS), nylon and other block plastic body into the required shape (if the size of less than 300mm and simple structure is directly processed once formed, if the structure of the shape is irregular or If the size is irregular or larger than 300mm, the part is generally divided into several small pieces and processed separately), and then after assembling, the final part to meet the design requirements of the size. This method of manufacturing rapid prototyping prototypes is the earliest, with relatively short processing cycle and low purchase price, and is mainly used for small and medium-sized parts with relatively simple structure and low demand, such as pillars, sub-instrument panels and door guards.

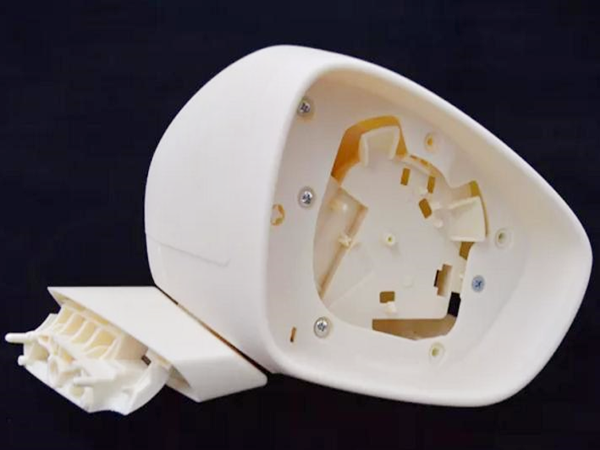

Due to the modeling needs of automotive interior and exterior parts, the parts usually processed are irregularly round or square, when the size of the parts is larger than 300mm or the structure is irregularly modeled, if a whole block of plastic is used directly to process the parts, it will lead to an exponential increase in cost. Therefore, the actual manufacture of irregularly shaped parts, the parts will be divided into several parts according to structural characteristics, and then rough machining to obtain the general shape, and then use special adhesives to glue the parts of each part to form the overall contour of the part shape, and then finally together for finishing, which can effectively reduce the waste of material caused by the structure of the parts, reduce the cost of parts. The disadvantage is that in the back of the parts can be seen in the parts of the parts of the chunk between the more obvious bonding traces, parts bonding position strength is poor, easy to crack. Figure 1 shows the prototype of rapid prototyping completed by CNC machine tool.

2\3D Printing

3D printing is a technology that constructs objects by printing them layer by layer using powdered metal or plastic as the basis. 3D printing technology has a wide range of applications, and rapid prototyping is one of its important directions. The prototype parts obtained through 3D printing manufacturing have a shorter cycle time and can achieve shaped structure printing, and the overall dimensional accuracy can be adjusted according to the actual demand to meet the different needs of different occasions. General 3D printing can manufacture the same range of parts as those processed by CNC machine tools, and is suitable for rapid prototyping of parts such as columns, sub-instrument panels and door guards.

The common plastic materials used in 3D printing are ABS-like plastic [acrylonitrile (A), butadiene (B), styrene (S) terpolymer of three monomers], nylon, nylon plus glass fiber and transparent photosensitive resin, etc. The advantage of ABS-like plastic is low unit price, good molding performance, suitable for structural parts with low strength requirements; nylon has good strength performance, better heat resistance than ABS-like plastic, but the price is higher The nylon plus glass fiber is a strengthened version of the performance of ordinary nylon, suitable for parts with high strength requirements; 3D printing photosensitive resin commonly known as UV resin, mainly composed of polymer monomer and pre-polymer, which is added with photoinitiator, in a certain wavelength of ultraviolet light (250-300nm) irradiation will immediately cause polymerization reaction to complete the solid state conversion, photosensitive resin curing speed, high molding accuracy, good surface effect, high mechanical strength (surface effect). It has the advantages of fast curing, high molding accuracy, good surface effect, high mechanical strength (comparable to ABS-like strength), low odor, high versatility and storage resistance.

3\Vacuum Casting Mould

Soft molds mainly refer to silicone molds and FRP molds.

Silicone molds are generally designed using CNC machine tools or 3D printing, and then the parts are used for rapid turning process to make the molds. This production process has short cycle time and low cost, and can use vacuum injection, pressure injection and low-pressure infusion processes for product production. Silicone rubber mold production process is suitable for small batch production (less than 100 pieces), product material strength and dimensional accuracy requirements of high products, product performance close to conventional ABS plastic.

The silicone rubber used for mold making is two-component liquid silicone rubber, and there are two types of moulds: condensation moulds and additive moulds according to the rubber composition. Generally speaking, the shear strength of condensed silicone is low, easy to be torn in the mold manufacturing process, so it is suitable for simple structure, reinforcement less parts; plus molding silicone mechanical properties and heat aging performance is good, suitable for the manufacture of relatively high size requirements of the mold.

At present, silicone mold production of small batch parts has been widely used in the trial production of interior and exterior trim prototypes in the pre-development stage of automobiles. The most widely used parts are small and medium-sized injection-molded structural parts such as door guards, pillars and door sill guards in the interior of automobiles.

FRP (fiber reinforced plastics) is a composite material with glass fiber and its products (glass cloth, tape, felt, yarn, etc.) as the reinforcing material and synthetic resin as the matrix material, as shown in Figure 3. FRP mold based on FRP material, similar to silicone mold, made by using rapid turning process, is usually used for automobile roof trim and carpet trim and other molded molding classes, simple structure of medium and large decorative parts. FRP molds are suitable for parts produced by the molding process, blister molding process and foam molding process.

The general production process of FRP mold is: part modeling → brush master mold → brush convex mold → brush concave mold → NC processing → welding mold frame → test mold → local correction → acceptance. Usually the development cycle of a pair of FRP mold is about one week, and the cost is only 1/10 of the official mold, which is a short-cycle, low-cost prototype mold. This kind of mold production method can also meet the manufacturing needs of small batch products (100~1000 sets).

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.