Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Automotive heat exchangers are used to transfer heat between two media of different temperatures that are in thermal contact with each other. For example, in internal combustion engines, engine coolant flows in a circular motion through radiator coils and air flows through these coils to cool the engine. The automotive industry is an important segment for heat exchanger applications, and by the end of 2014, the automotive segment had a share of more than 25% of the global heat exchanger market.

China has significantly increased its market share since the early 2000s and today has the highest share of more than 50% in the Asian automotive heat exchanger market. The demand for passenger cars and light commercial vehicles is expected to grow over the forecast period, leading to high demand for automotive heat exchangers in China.

The increasing demand for reducing the weight of vehicles has led OEMs to replace heavier materials such as iron and steel with lighter materials such as plastic and aluminum. The automotive heat exchanger market has followed this trend. In addition, previous heat exchanger designs and structures cause corrosion, decomposition, sludge settling, and dust particles can lead to fouling, which leads to reduced heat transfer and lower efficiency, resulting in higher fuel consumption.

The overall heat exchanger market in China is showing a high industrial growth rate, mainly due to the diversification of heat exchanger applications and the increasing demand for heat exchangers. The demand for automotive heat exchangers depends on several factors such as production and demand for automobiles and current vehicle ownership. In emerging and developing countries such as China, the demand for automotive heat exchangers is driven by the production of new vehicles. Moreover, automotive heat exchanger manufacturers in the China region have started investing heavily in lightweight automotive materials such as aluminum, which is expected to significantly boost the demand for automotive heat exchangers in the region.

Most Chinese automakers are committed to using aluminum as a lightweight material in component production, and revisions to emissions standards are expected to increase the use of heat exchangers. In addition, when lightweight structures are designed into automotive heat exchangers, it will further increase the manufacturing cost of manufacturing automotive heat exchangers. While managing costs while meeting increasing product complexity is a significant challenge for automotive heat exchanger suppliers.

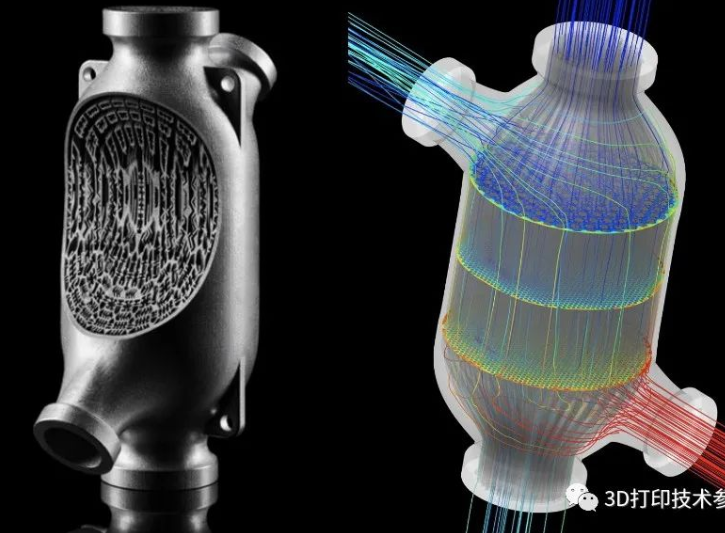

Heat exchanger, as the core component of automotive heat sink system, matches the iteration speed of the model. In the future, heat exchangers will inevitably need to ensure their basic performance requirements and their cost control requirements, from the structure, materials, processes and other aspects, the application of new design, new materials, new technologies to achieve the overall weight reduction of the car, to the direction of compact structure, overall lightweight and efficient performance. This is almost exactly in line with the manufacturing characteristics of 3D printing technology.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.