Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Forming Method: Preform Mould, Silicone Mould, Die Casting

Product Material: Rubber, Metal, Plastic, Steel, Aluminium, Copper

Place Of Origin: China

Product: Vehicle Mould, Household Appliance, Household Product

Packaging: carton box, wooden box;as per customer's requirement

Transportation: Ocean,Land,Express

Supply Ability: 1000

Port: Ningbo

Payment Type: T/T

Incoterm: FOB,DDU

Vacuum Casting Pastic Accessories

Product Description

A prototype is also called a model or a mock-up. Jiongke has been using CNC machining, SLA prototyping, vacuum casting , and all inclusive surface treatment techniques to make top class functional prototypes, presentation models, casting patterns and production parts from plastic, elastomeric and metal materials for various industries.

We are able to process high precision CNC machining and rapid prototyping with stable and reliable quality. We don't offer any ready made parts and are manufacturing the custom parts from your drawings or existing samples. We can make the parts with Resin, ABS, Nylon and other as required. We pride ourselves on our flexibility and adaptability in delivering parts, whether the requirement is for small or large quantities.

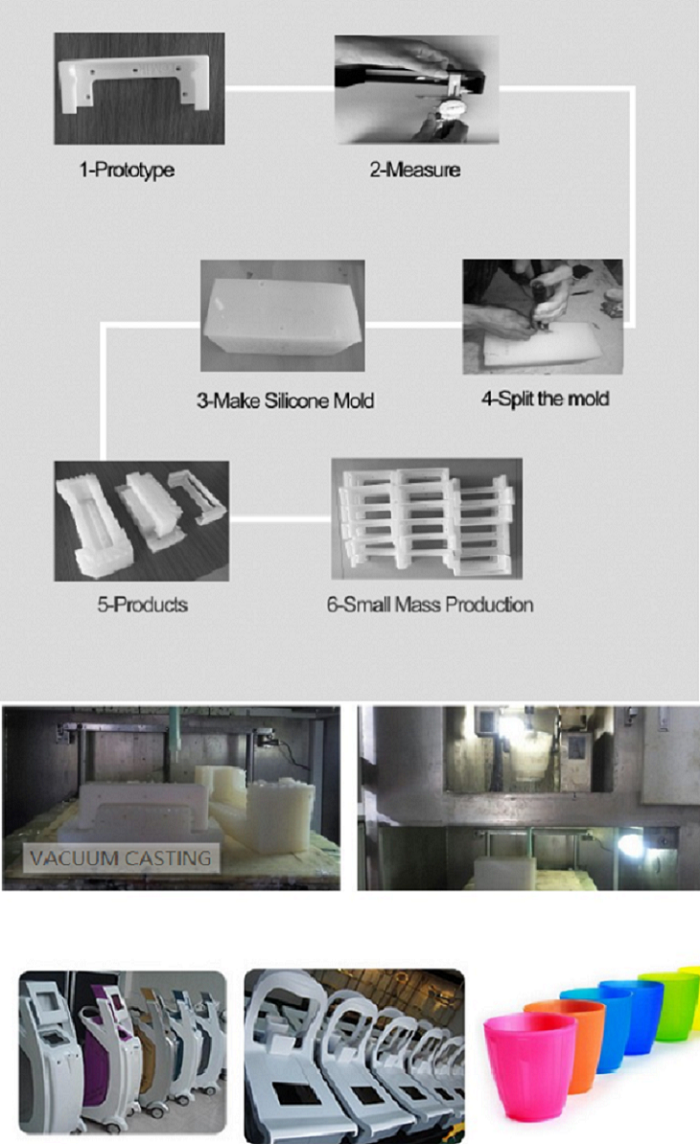

Vacuum casting mould, also known as vacuum complex mode.Under vacuum conditions in both the castable for deaeration,stirring, preheating, note type, and at 60 ℃, 80 ℃ in the constant temperature box of 2 to 3 hours of secondary curing process.Suitable for small batch trial production of the product development process, the structure is relatively complex, uniform wall thickness, satisfy a certain functional requirements of test samples.

Type Name: Vacuum Casting Plastic Accessories

Key Words:Small Batch Parts Service,Customized Pllastic Accessories,Silicone Mould Service

Service Type:

1. Metal and Plastic Rapid Prototype,Rapid prototype service ,

2. CNC Machining Parts: Turning, Milling, Stamping, Bending, Tapping, Riveting, Gear cutting, Wire-cutting, CNC Machining Service etc.

3. . SLA & SLS 3D Printing ,3D Printing Service

4. Industrial design, 2D & 3D drawings design

5. Silicone Mold, Vacuum casting Service

Material available;ABS,PC,PE,Nylon etc

Surface treatment:Painting,Electroplating etc.

Tolerance:+/-0.05mm

File Format:STP,STEP,STL,UG

Production capacity:According to Customer`s Drawings

Lead time:5-30 Days,According to Quantity(ASAP)

PROCESS

Product Categories : Vacuum Casting Service > Vacuum Casting Service

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.